Blog

Troubleshooting Claas Jaguar Stone Detector Faults (STOP ROCK)

Introduction

For a forage harvester operator, the STOP ROCK system (Stone Detector) is the most important insurance policy on the machine. It stands between a hidden rock and a $20,000 repair bill for your chopping drum.

However, nothing is more frustrating than the “Boy Who Cried Wolf”—a stone detector that keeps stopping the feed rollers when there is no stone (false alarm), or worse, throws a fault code and refuses to work at all.

In this guide, we break down common Claas Jaguar stone detector fault codes, how to diagnose sensor issues, and when to replace the critical stop pawl solenoid.

How the STOP ROCK System Works

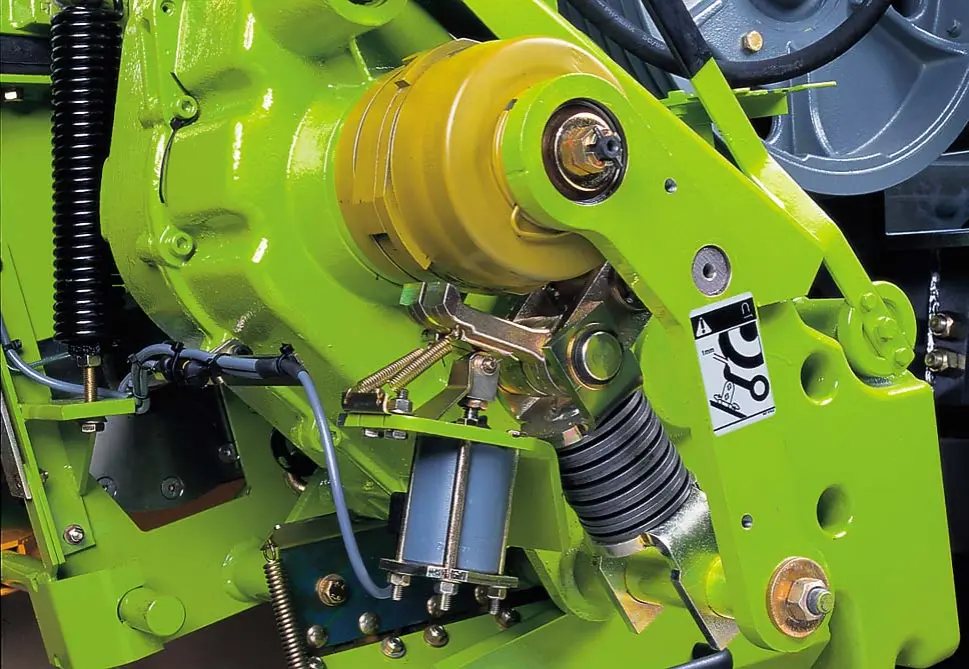

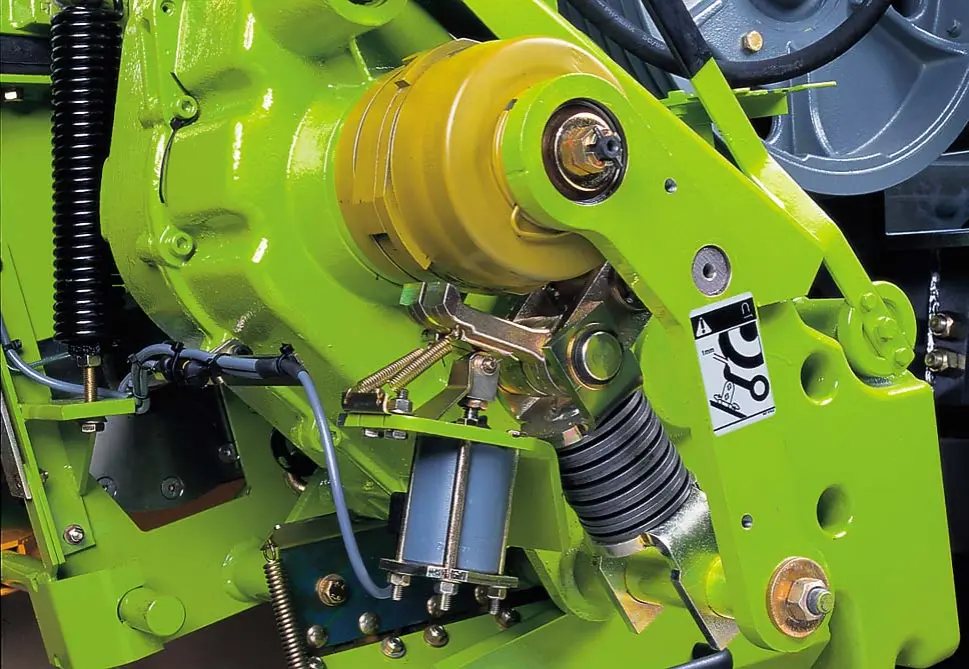

Before fixing it, you must understand it. The system relies on vibration/acceleration sensors mounted on the lower feed roller dampeners.

- Detection: When a stone hits the feed rollers, it causes a sudden vertical acceleration.

- Signal: The sensor sends a voltage spike to the onboard computer.

- Action: The computer triggers the Stop Pawl Solenoid, which instantly locks the feed drive mechanism, stopping the intake in milliseconds.

Common Fault Messages & Codes

Depending on your CEBIS version (Jaguar 800 vs 900), the exact numbers may vary, but the messages are consistent.

“Stone Detector Failure” / “Open Load”

This usually indicates an electrical break.

- The Culprit: Check the wiring harness leading to the stop solenoid. The harness near the feeder house is subject to constant vibration and can rub against the frame, causing a broken wire.

- The Fix: Inspect the plug connection at the solenoid valve. If the coil resistance is infinite, the solenoid is burnt out.

“Sensor Signal Implausible”

The computer is receiving confuse data from the sensors.

- The Culprit: Usually moisture or corrosion in the potentiometer/sensor connectors on the feed roller housing.

- The Fix: Clean the contacts with contact cleaner. If the error persists, swap the left and right sensors. If the error moves to the other side, the sensor is dead.

“Stop Pawl Did Not Engage”

The system tried to stop, but the mechanism didn’t lock.

- The Culprit: Mechanical seizure or a weak solenoid. The pawl might be rusted or packed with silage sap.

Troubleshooting: False Alarms (Stops with No Stone)

If your machine keeps stopping in heavy crops (like lump alfalfa) but there are no stones:

1. Sensitivity Settings

Check your CEBIS sensitivity settings. If it is set to 100% in uneven windrows, it will trigger on crop lumps. Dial it back to 70-80% and test.

2. Wear on Feed Rollers

Worn feed roller teeth or loose slats can cause “bumping” vibrations that mimic a stone impact.

- Check: Inspect your feed rollers. If the teeth are rounded, the crop feeds unevenly, causing vibration.

- Solution: Replace worn feed roller bars or slats.

3. The Dampener (Shock Absorber)

The sensors are mounted on dampeners. If the rubber dampener is worn out, normal vibrations are amplified, tricking the sensor.

The Critical Part: The Stop Solenoid

The heart of the system is the electro-hydraulic solenoid valve that engages the stop pawl.

- Lifespan: These coils heat up and eventually fail after a few seasons.

- Agmishop Solution: We stock high-quality replacement solenoids compatible with Claas Jaguar 800 and 900 series. They are built to withstand heat and vibration, ensuring the pawl engages only when it needs to.

Conclusion

Do not bypass your stone detector! We have seen farmers disconnect the system to “get through the day,” only to feed a rock into the chopper an hour later. The cost of a new chopping drum is not worth the risk.

Diagnose the code, check the wiring, and replace faulty sensors or solenoids immediately.