Blog

Cracked Corn in Silage: Why Kernel Processing Matters & How to Fix Poor Results

Introduction

In the world of dairy and beef farming, cracked corn is not just chicken feed—it is the key to high-energy silage. When harvesting maize with your forage harvester, the goal is simple: every single kernel must be shattered.

If you find whole, uncracked kernels in your manure or silage pit, you are essentially throwing money away. Starch availability drops, and milk production suffers.

In this guide, we explain the science behind corn cracking, why your “Corn Cracker” might be failing, and how high-quality aftermarket replacement rollers can restore your harvest quality.

What is “Cracked Corn” in Forage Harvesting?

When we talk about cracked corn in the context of silage, we are referring to the Kernel Processing Score (KPS).

The Science of Starch

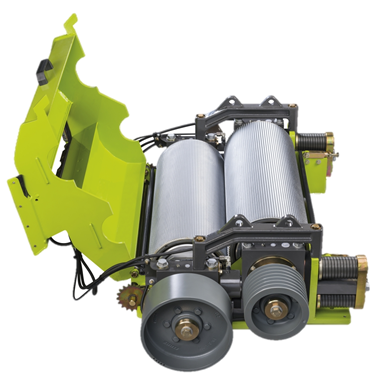

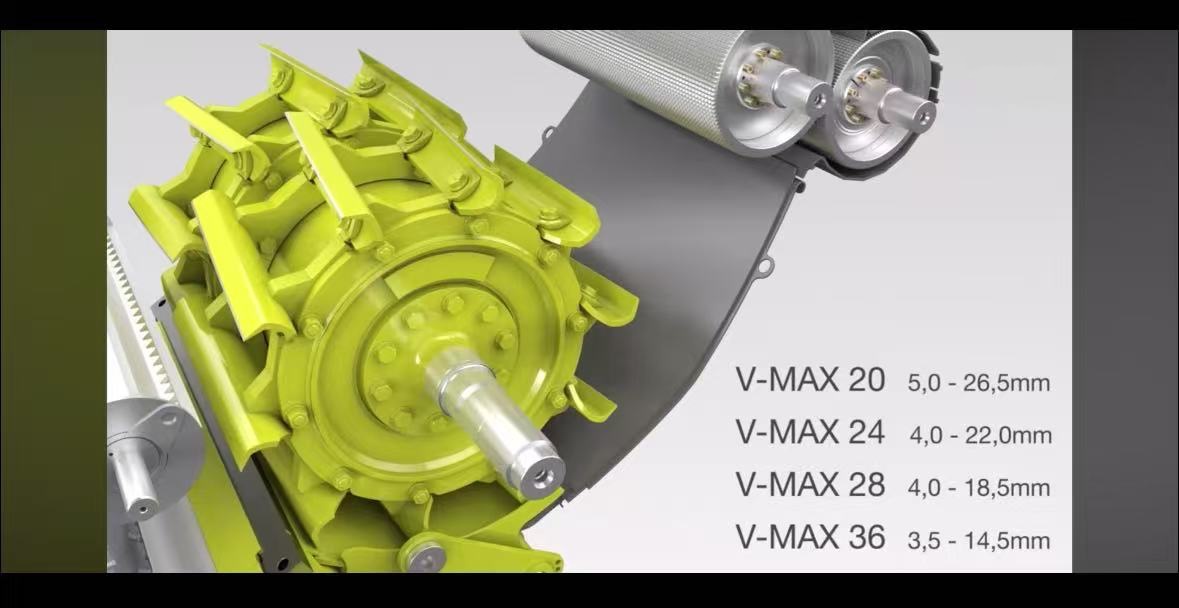

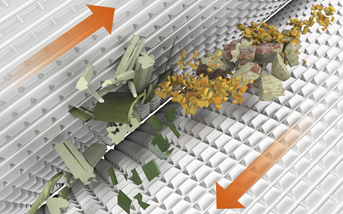

Cows cannot digest whole corn kernels. The outer shell is too hard. The job of your forage harvester’s Corn Cracker (MCC, KernelStar, or Shredlage unit) is to pulverize these kernels.

- Ideal Result: Fully pulverized kernels (Cracked Corn).

- Bad Result: Whole or merely “nicked” kernels (Uncracked).

Why “Uncracked” Corn is a Disaster

If your kernels aren’t cracked:

- Starch Loss: The energy passes right through the cow.

- Feed Costs Rise: You have to buy supplemental grain to make up for the lost energy.

Signs Your Corn Cracker Rollers Are Worn Out

The number one reason for poor corn cracking is worn-out hardware. Even the most powerful Claas Jaguar 960 or John Deere 8000 cannot perform if the cracker rollers are smooth.

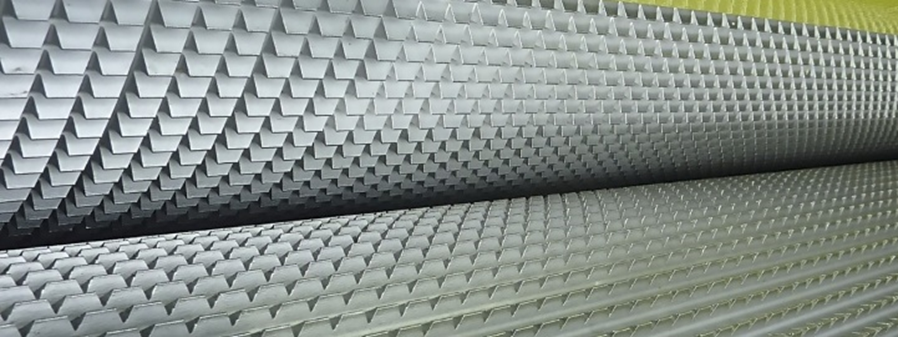

The “Fingernail Test”

Inspect your rollers. The teeth should be sharp. If you can run your fingernail over the teeth without it catching, the edges are rounded. Rounded teeth cannot grab and shear the kernel; they just let it slip through.

Incorrect Gap Settings

Sometimes it’s a setting issue, but often, farmers tighten the gap to compensate for worn rollers. This causes vibration and heat but doesn’t solve the problem of dull teeth.

Solutions: OEM vs. Aftermarket Cracker Rollers

When you realize your silage quality is dropping, you need new rollers. But do you need to pay dealership prices?

The Agmishop Alternative

At Agmishop Agriparts, we manufacture replacement corn cracker rollers that rival the original equipment.

Heavy-Duty Materials

Our rollers are made from hardened alloy steel, designed to withstand the abrasive nature of corn stalks and stones.

Precision Tooth Profiles

Whether you need a saw-tooth profile for aggressive shredding or a standard profile, our rollers are machined to ensure aggressive processing. We ensure that you get perfectly cracked corn every time.

How to Maintain Your Corn Cracker for Peak Performance

Regular Inspection

Check your wear plates and rollers daily during the harvest season.

Replace in Pairs

Always replace both rollers (upper and lower, or fast and slow) at the same time. Mismatched wear leads to vibration and poor cracking.

Conclusion: Don’t Leave Starch in the Field

Achieving perfectly cracked corn is the difference between a profitable year and a breakeven year. Don’t let worn-out parts rob your herd of nutrition.

Upgrade your forage harvester with Agmishop’s premium aftermarket cracker rollers. Get the “crack” you need at a price that makes sense.

Shop Agmishop’s Corn Cracker Rollers Now !

| Optimal (> 70%) | High | Maximum milk production and digestion efficiency. | Maintain current settings. |

| Adequate (50% – 70%) | Medium | Some starch is lost in manure. Potential revenue loss. | Check roller gap settings and spring tension. |

| Poor (< 50%) | Low | Significant Loss. Cows cannot digest the energy. | Inspect rollers immediately. Teeth are likely worn smooth and need replacement. |

“As the table shows, a ‘Poor’ score means you are feeding expensive corn to your cows only to see it pass right through them.

Don’t settle for < 50%. If your KPS is low, the culprit is often worn roller teeth. Upgrade to Agmishop’s High-Performance Cracker Rollers to get back to the Optimal (> 70%) range.”