Blog

How to Adjust the Shear Bar on a Claas Jaguar (Step-by-Step)

Introduction

In the world of forage harvesting, the distance between your knives and the shear bar (or counter-knife) is the difference between profit and loss.

A gap that is too wide results in “mushy” silage, long particles, and a massive spike in fuel consumption. A gap that is too tight risks metal-on-metal collision.

For Claas Jaguar owners (800 and 900 series), keeping this setting precise is daily homework. In this guide, we walk you through the correct procedure to adjust your shear bar for the perfect “scissor cut,” and knowing when it’s time to stop adjusting and start replacing.

Why the Shear Bar Setting Matters

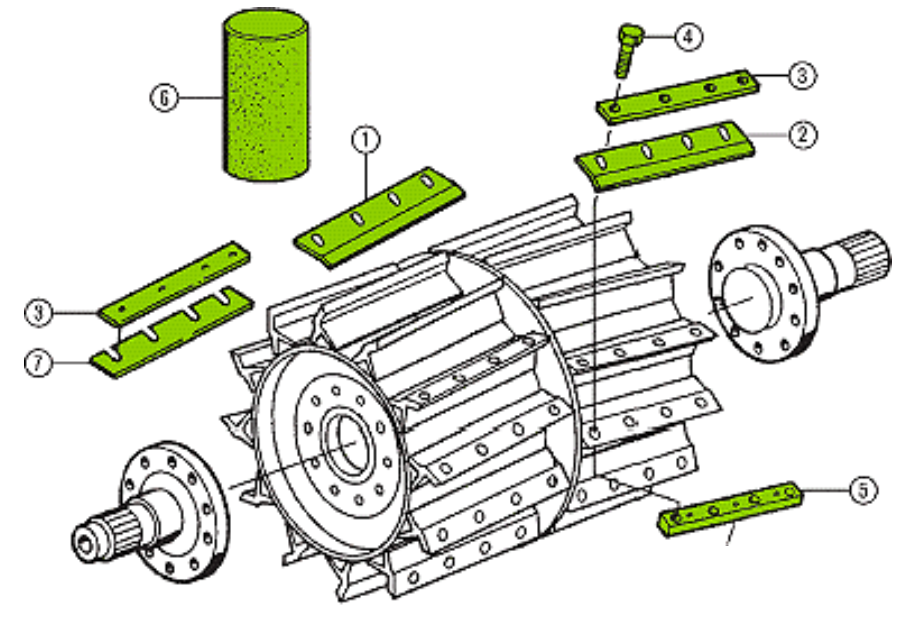

Think of your chopping drum like a pair of scissors. The rotating knives are one blade, and the stationary shear bar is the other.

If you try to cut paper with loose scissors, the paper folds instead of cutting. The same happens to your corn or grass.

- Fuel Economy: A precise gap reduces the power needed to chop, saving up to 10% in diesel.

- Silage Quality: A sharp, tight cut ensures optimal packing in the bunker and better digestion for the herd.

Pre-Adjustment Checklist: Safety First

⚠️ WARNING: The chopping drum is dangerous. Never work on the machine while the engine is running unless performing the specific cab-controlled adjustment procedure.

- Sharpen Knives FIRST: You cannot adjust a shear bar to dull knives. Always run a full sharpening cycle before adjusting the shear bar.

- Clean the Mechanism: Ensure the worm gears or motors that move the shear bar are free of dried sap and rust.

The Adjustment Procedure (Claas CEBIS System)

Most modern Claas Jaguars (Types 492, 494, 497, etc.) use an automated system involving knock sensors.

Step 1: Engage the Cylinder

Start the chopping drum and bring it to the rated engine speed (usually idle or low RPM depending on your specific manual).

Step 2: Select “Shear Bar Adjust” in CEBIS

On your cab monitor (CEBIS), navigate to the maintenance menu and select the shear bar adjustment icon.

Step 3: The “Knock” Sensor Process

When you press start, the machine will slowly move the shear bar closer to the spinning knives.

- How it works: The machine listens for a specific vibration (a light “tick-tick-tick”) caused by the knives barely touching the shear bar.

- Retraction: Once the knock sensor detects contact on both sides (left and right), the motors automatically retract the shear bar by a specific distance (usually 0.1mm to 0.3mm).

Step 4: Visual Check

Shut down the machine (wait for full stop!) and open the housing. Use a feeler gauge to verify the gap is consistent across the width of the drum.

When Adjustment Does Not Work: Signs of Wear

You can keep adjusting, but eventually, you run out of steel. If you experience the following, it is time to replace the shear bar:

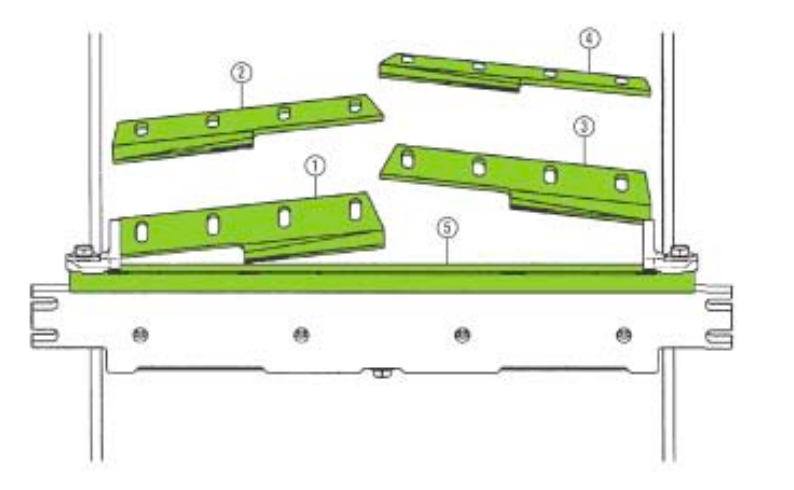

- Rounded Edge: Run your finger (carefully!) along the cutting edge of the shear bar. It should be sharp and square (90 degrees). If it is rounded like a pebble, no amount of adjustment will fix the cut.

- U-Shape Wear: The center of the bar often wears faster than the sides. If the gap is tight on the sides but wide in the middle, you need a new bar.

- Breakage: Inspect for chunks of metal missing due to stone impact.

Upgrade Your Cut with Agmishop Parts

When it’s time to replace, Agmishop offers premium aftermarket shear bars designed specifically for the Claas Jaguar.

- Universal Fit: Our “Universal” shear bars are designed to work with both Corn and Grass knives, saving you the hassle of swapping bars mid-season.

- Premium Steel: Heat-treated to withstand the impact of high-horsepower harvesting.

- Cost Effective: Get the same cutting performance as the OEM part for a fraction of the price.

Compatible Models: Claas Jaguar 800, 900, 960, 980 Series. Replaces OEM Parts: 984339.1, 0009843391, and more.

Conclusion

A properly adjusted shear bar is the secret to a high-capacity harvest. Make it a habit to sharpen and adjust daily.

And when the edge is gone, trust Agmishop to get you a replacement fast. Don’t let a dull bar burn your fuel budget.