Blog

How to Replace Claas Jaguar Feed Rollers | Maintenance Guide

Introduction

The feed roller is the “mouth” of your Claas Jaguar. It determines how smoothly the crop flows into the chopping drum. However, after hundreds of hours of harvesting corn or grass, the teeth on the rollers wear down, leading to uneven chop lengths and feeding blockages.

If you’ve noticed your machine struggling to pull in crops or the grip is slipping, it might be time for a replacement.

In this guide, the Agmishop technical team walks you through the general process of replacing a feed roller (specifically the Upper Rear or Front rollers) on a Claas Jaguar forage harvester.

(Pro Tip: Looking for affordable replacement parts? Check out our Claas Jaguar Compatible Feed Rollers here.)

Signs Your Feed Rollers Need Replacing

Before you start unbolting, confirm the wear:

- Rounded Teeth: The aggressive edges of the roller bars are smooth.

- Poor Feeding: The crop bunches up at the intake.

- Stone Detector Errors: Worn rollers can sometimes cause vibration or play that triggers false stone detection alarms.

Tools and Safety Preparation

⚠️ SAFETY FIRST:

- Lock the header: Ensure the attachment (Orbis or Pick-up) is removed or securely locked in the raised position.

- Stop the engine: Remove the key and wait for all moving parts to come to a complete standstill.

- Wear protective gear: Heavy gloves and safety boots are mandatory. These rollers are heavy (approx. 25kg for an upper rear roller).

Tools Recommended:

- Impact wrench

- Socket set (Metric)

- Lifting strap or hoist (to support the roller weight)

- Pry bar

Step-by-Step Replacement Guide

(Note: This is a general guide. Always refer to your specific Claas Jaguar Service Manual for torque settings and model-specific variations like the 800 or 900 series.)

Step 1: Access the Intake Assembly

Remove the front attachment (header) to expose the intake housing. You may need to open the side shields of the harvester to access the drive belts or chains on the side of the feeder house.

Step 2: Relieve Tension

The feed rollers are under spring or hydraulic tension to compress the crop. You must release this tension before removing the roller.

- Locate the tension springs or hydraulic cylinders on the side.

- Use the appropriate tool to release the pressure safely.

Step 3: Disconnect the Drive

On the drive side of the intake housing, remove the drive chain or cardan shaft connected to the specific roller you are changing (e.g., the Upper Rear Roller).

Step 4: Remove the Bearing Flanges

Unbolt the bearing housings on both the left and right sides.

- Tip: Inspect the bearings while you are here. If the roller is worn, the bearings are likely tired too. Agmishop supplies both rollers and matching bearings.

Step 5: Extract the Old Roller

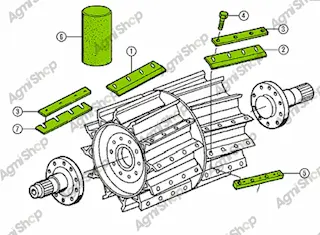

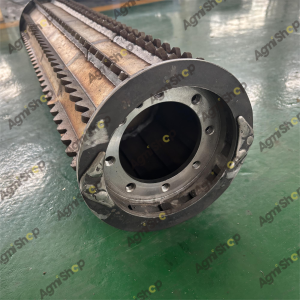

This is a two-person job or requires a hoist. A standard Claas Upper Rear roller (Reference OEM: 09863261) weighs about 25kg and is over 700mm long. Carefully slide the roller out of the housing.

Step 6: Install the New Agmishop Roller

Claas 800 series FEED ROLLER 09863261【Replace OEM#:09863260】

Claas 900 series 09062020 – claas feed roller – upper rear

- Compare: Ensure your new aftermarket part matches the dimensions of the old one. Agmishop parts are manufactured to precise OEM specs (e.g., φ184*718.05mm).

- Insert: Slide the new roller into position.

- Bolt: Reattach the bearing flanges and tighten to the manufacturer’s torque specifications.

- Reconnect: Reattach the drive chains/shafts.

Step 7: Calibration

Once everything is reassembled, reset the tension. Run the machine at low RPM to check for smooth rotation and ensure there are no unusual noises before heading back to the field.

Why Choose Aftermarket Feed Rollers from Agmishop?

Farmers and dealers often ask: “Is an aftermarket roller as good as the original?”

At Agmishop, we manufacture our parts in our own family-owned factory in China, with over 10 years of experience supplying dealers worldwide.

- Cost Efficiency: Save 30-50% compared to OEM dealer prices.

- High Durability: We use Non-magnetic, wear-resistant stainless steel material to match the hardness and wear resistance of the original Claas parts.

- Perfect Fit: Our parts, such as the replacement for Claas 09863261【Replace OEM#:09863260】, are drop-in replacements. No modification needed.

Ready to prepare for the harvest season? 👉 Shop our full range of Forage Harvester Parts here

User Feedback

“Ordered a set of feed rollers for my Jaguar 850. Arrived quickly to the UK and fit perfectly. The machine is feeding like new again.” — Mark T., Agricultural Contractor

Need Help Finding the Right Part?

If you are unsure about the part number, verify the dimensions or send us a photo. Our team is online 24/7 to assist you via WhatsApp or Email.