Blog

Ultimate Corn Chopper Comparison: Claas vs. John Deere vs. Krone. Which Handles the Harvest Best?

Introduction

When farmers and contractors talk about a “corn chopper,” they are talking about the beast of the harvest season: the Self-Propelled Forage Harvester (SPFH).

Choosing the right corn chopper is one of the biggest financial decisions an agricultural operation can make. It’s not just about horsepower; it’s about throughput capability, chop quality (kernel processing), fuel efficiency, and, crucially, long-term maintenance costs.

The market is dominated by giants like Claas, John Deere, and Krone, often utilizing specialized headers from manufacturers like Kemper.

In this article, we compare the leading corn chopper brands to help you understand their distinct advantages in the field.

Claas Jaguar: The Global Benchmark

Claas is arguably the market leader in the forage harvester world. The “Jaguar” series is practically synonymous with high-performance corn chopping.

Key Features & Performance

Known for the legendary V-MAX chopping drum and excellent straight-line crop flow. Claas machines are praised for their reliability and high resale value.

The Header Connection:Orbis

Claas typically pairs their machines with their own Orbis corn headers.

- Advantage: They are famous for smooth feeding and low maintenance needs due to fewer moving parts compared to traditional chain headers.

John Deere: Technology and Integration

John Deere’s 8000 and 9000 series forage harvesters are massive contenders, particularly strong in the Americas.

Integrated Harvest Technology

- Deere focuses heavily on integrated technology, such as the HarvestLab sensor. This allows for real-time constituent analysis (measuring moisture, starch, etc., on the go). Their DuraDrum™ choppers are designed for durability.

The Kemper Partnership

- While John Deere manufactures their own headers, many of their “corn choppers” in the field are equipped with renowned Kemper rotary headers. This combination is known for aggressive intake in tough, down corn conditions.

Krone BiG X: The Powerhouse Option

Krone is known for pushing the boundaries of horsepower. Their BiG X series includes some of the most powerful agricultural machines on the planet.

Massive Throughput Design

- Krone emphasizes massive throughput. They use unique features like six pre-compression rollers (feed rollers) instead of the standard four, ensuring an incredibly uniform crop mat entering the drum for consistent chop length.

- The Header Connection: Krone uses their own EasyCollect headers, which use a unique collector principle that requires less power to operate than some competitors.

A Special Mention: Kemper Headers (The Universal “Chopper”)

It is impossible to discuss “corn choppers” without mentioning Kemper.

While not a harvester manufacturer itself, Kemper is the undisputed king of rotary corn headers. You will see Kemper headers (often branded or painted differently) on John Deere, New Holland, and older Claas machines.

- Why it matters: For many farmers, the “chopping” starts at the header. Kemper’s row-independent technology revolutionized how corn is harvested, allowing for faster speeds and better handling of lodged (fallen) crops.

Comparative Analysis: What Truly Matters?

When comparing these brands, the decision often comes down to three factors:

A. Chop Quality and Kernel Processing

A powerful engine is useless if the kernels aren’t cracked.

- Claas uses the MCC (Multi Crop Cracker).

- John Deere uses the KernelStar or Premium KP.

- Krone uses the OptiMaxx cracker. All are effective, but they all rely on one thing: sharp, durable rollers.

B. Efficiency and Flow

How fast can the machine process tonnes per hour without blocking? Claas is often lauded for its direct crop flow, while Krone’s six feed rollers offer superior pre-compression.

C. Maintenance Costs (The Critical Factor)

This is where the reality of owning a corn chopper hits home. Regardless of whether you choose green, lime green, or yellow, these machines eat metal.

- Knives dull.

- Shear bars lose their edge.

- Feed roller teeth wear down.

- Wear plates get thin.

High-horsepower machines put immense stress on these components. Relying solely on OEM (Original Equipment Manufacturer) parts for maintenance can significantly eat into harvest profits.

The Agmishop Advantage: Keeping Your Chopper Running

No matter which brand of corn chopper wins your comparison, they all need replacement parts to keep running at peak performance.

At Agmishop Agriparts, we specialize in high-quality aftermarket wear parts that meet or exceed OEM specifications for all major brands.

- Running a Claas Jaguar? Check out our compatible knives and feed rollers.

- Using a John Deere with a Kemper header? We stock replacement Kemper header parts designed for aggressive harvesting.

- Need new wear plates to protect your investment? We have cost-effective solutions that fit perfectly.

Don’t let expensive OEM parts slow down your harvest. Choose Agmishop for reliable, factory-direct alternatives.

Conclusion

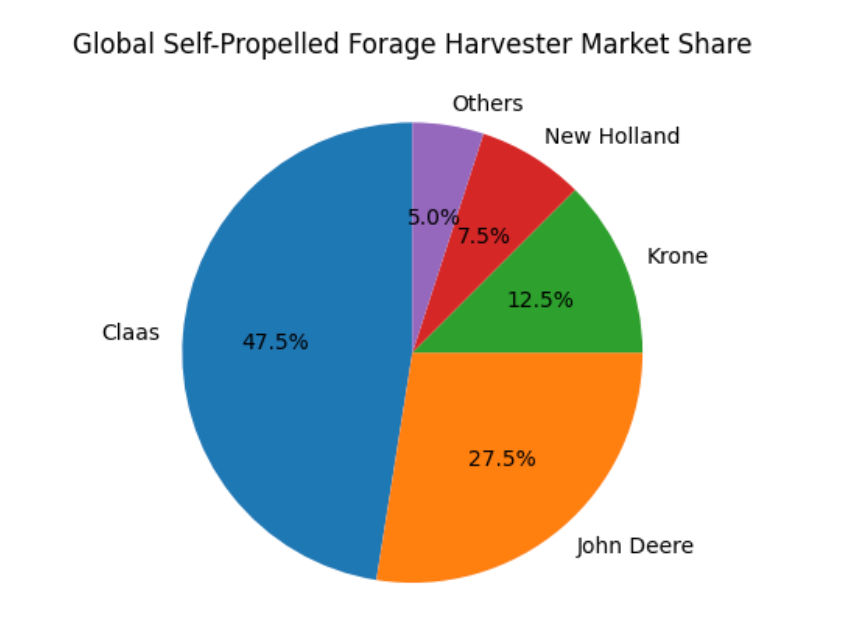

- Global Self-Propelled Forage Harvester Market Share Estimates

| Brand Name | Est. Global Market Share | Primary Market Strength | Key Strengths |

| Claas | 45% – 50% | Europe & Global | Market leader, high resale value, efficient crop flow (V-MAX). |

| John Deere | 25% – 30% | North America | Massive dealer network, integrated technology (HarvestLab). |

| Krone | 10% – 15% | Contractors (Global) | High horsepower segment (BiG X), throughput capacity. |

| New Holland | 5% – 10% | Europe & Americas | Versatility (FR Series), fuel efficiency. |

| Others | ~5% | Niche Markets | Includes brands like Fendt, Rostselmash, and Gomselmash. |

The “best” corn chopper depends on your specific acreage, dealer support in your area, and budget. Claas offers proven reliability, John Deere brings integrated tech, and Krone provides sheer power.

However, the secret to a successful harvest isn’t just the brand name on the side of the machine—it’s the quality of the wear parts inside it. Keep your corn chopper sharp, efficient, and profitable with the right maintenance strategy.